How Talent And Technology Together Supercharge Factory Productivity

Why this matters now: the productivity imperative Factories are no longer just about machines and maintenance manuals. Recent industry...

Category: Uncategorized

Sign in

1. The Core Tools for Operational Excellence

2. PDCA Cycle: Plan-Do-Check-Act the core tool for OpEx

a. Plan

b. Do

c. Check

d. Act

e. Summary

1. The Core Tool for Operational Excellence

Why do you need OpEx tools when you improve? In the OpEx system, if you want to bring people into your process, build ownership together with others and train them and build the organization, having methods and tools helps you to deliver a message. Methods and tools are a faster way to solve problems.

OpEx Tools make training others easier and faster and it’s a faster way to hold the gains. A strong reason for using methods and tools is that a step-by-step approach will make sure that you are more successful when you are solving the problems.

2. PDCA Cycle: Plan-Do-Check-Act the Core Tool for Op-Ex

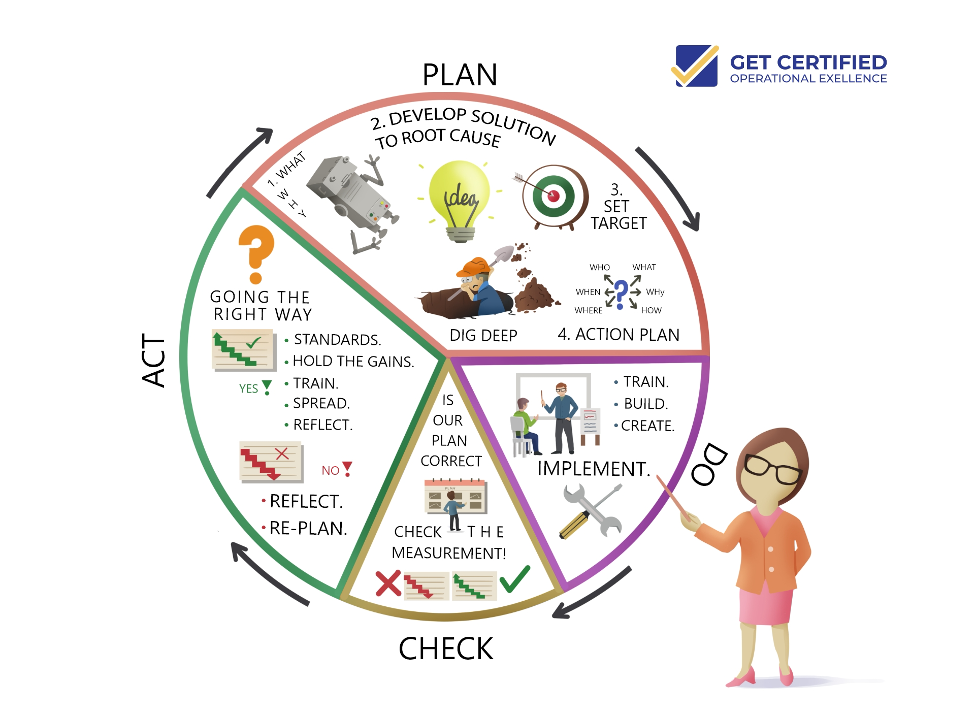

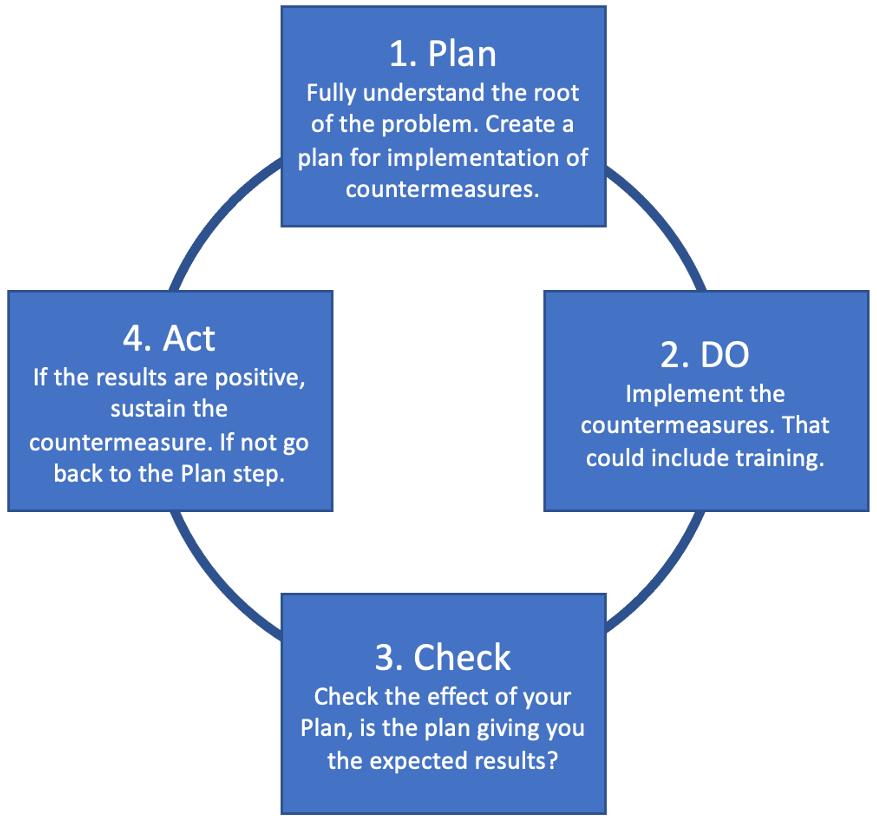

PDCA stands for Plan, Do, Check, Act and is the core tool for Operational Excellence.

The reason why so many improvement projects fail is that the PDCA cycle is not completed. Activities targeted at reducing the loss are often poorly planned and then subsequently implemented without thought. The results, good or bad, are not analyzed therefore no action can be taken to learn from the outcome. The likely upshot is either a poorly sustained result or a subsequent improvement project not utilizing the reasons why the initial attempt failed.

Using the PDCA approach a project is properly planned, followed by a controlled implementation of the improvement activities. The outcome of these activities is checked with resultant actions taken to either sustain the improvement or to understand why the results were not to the expected level. PDCA is a circular process, therefore actions can be fed into a further PDCA cycle.

In order to plan any improvement, it is critical to define the problem you are trying to solve. This definition should be clear, easy to comprehend, and most importantly be a shared understanding between everyone involved in the improvement project. It is important to link the problem to a business need so that the improvement will have a positive impact on company performance. It is also important to define a target for the project. This can then be used to calculate the potential financial savings which may be generated.

Failure Modes

Once the project is defined, it is important to identify as many failure modes as possible. The more comprehensive the identification, the more likely the underlying failure modes will be discovered. It is important to consider all possible failure modes during this step to avoid preconceptions of the root cause steering the project in the wrong direction. A data collection system can be used to help identify the failure modes. Once enough data has been captured, it can be used to prioritize the failure modes, helping to target your resources to the most beneficial areas.

With the failure modes identified and prioritized, you are then ready to carry out root cause analysis in order to understand the reasons behind each one. With the root causes established, appropriate countermeasures can be identified, each one targeted to reduce the loss in each specific area.

Countermeasures

The final part of this step is to plan the deployment of each countermeasure. To do this each countermeasure is listed out and assigned an owner and a due date. The relevant resources required are also identified and planned at this stage, as well as when the countermeasure work will take place. This is especially important if you need to interrupt a production schedule for example, as time will need to be allocated to allow you to carry out the improvement activities.

With all the above complete, the project can move on to the next stage of the PDCA cycle.

With all planning finalized, it is time to carry out the improvement activities. These could range from physical improvements to a machine, adjusting the process flow for product design, to training in any area of the business. The activities are carried out in accordance with the detailed planning created for each countermeasure.

Communication and Scheduling

It is important that good communication between the team is in place during the implementation of the countermeasures. Frequent team meetings should happen, especially before and after the countermeasure work is carried out. It is also important that the work stays on schedule. Adherence to time planning, especially in the case of using shared resources is vitally important.

With the Plan and Do stages completed, it is critical not to stop at this point. The sustainable success of the project relies on the next two stages of the cycle being completed.

With the thorough planning completed and countermeasures implemented, it is now time to follow up on your results. This step is to verify how successful you have been in eradicating the failure modes identified and selected. It is also important to check how successfully the plan was implemented:

The answer to these questions will help to define what actions to take in the final stage of the cycle. It is important to note that whatever the level of success achieved in the project; actions will always be required to deliver a sustainable result.

Now that the results have been checked, it is time to define the actions required to sustain the result or to put it another way to hold the gains.

Sustain Your Improvements

With a positive result these actions will focus on standardization of the improvement activities. This can include training, performance indicator tracking and horizontal expansion of the countermeasures to other areas. The focus here is on ensuring that the result is sustainable.

With a less desirable result, the actions should guide the team into another PDCA cycle, beginning at the Plan stage. The team can take everything they have learned into this new planning phase, reassess the root causes & develop new countermeasures aimed at reaching the original target.

In summary, by ensuring that the loop is effectively closed at the end of a project, the use of the PDCA tool, Plan-Do-Check-Act, delivers sustainable improvements which can be expanded horizontally throughout any business. It is the core tool used throughout Operational Excellence and can be applied to any situation where improvement is required.