Three Phases of Change in Process Improvement

Prepare, Manage, and Sustain are not the only 3 phases of change you need to be aware of. In this article, we are describing the actual detailed...

Category: Uncategorized

Sign in

In this first article of Operational Excellence, I will tell you a little bit about how the puzzle pieces come together to be one system that can change your business. Keep on reading.

As the Founder and CEO of Lean Dimensions International I'm very proud to be able to show you and explain the model that has become somewhat of our trademark, because often when we talk about operational excellence, world class manufacturing, lean thinking, etc., if you ask somebody who's into it, ask them to explain everything as one system, they often struggle with that. Most of the explanations is hard to follow since there's a great deal of practitioners who doesn't see the system they see a toolbox.

The persons who are in charge are often engineers who are promoted into a position to lead the implementation of continuous improvement and the approach it with an engineer’s mind, a logical roll out plan that look at it as if it was only a technical concept.

There's a back side to that, that everything becomes technical. We believe that IQ times EQ becomes unity and results (IQ*EQ=Unity and Results). It's about technical aspects as well as emotional aspects that generate the results. There are of course engineers who understand that, however my experience is that it's not the majority.

Companies who are successful in their implementation have managed to address the emotional side to people to bond with them and with the system, and that's the point, it's a system, it's not a set of tools. The toolbox approach often shows up to be when you are asking people with an engineering mind-set to drive it. No offense to engineers, I'm an engineer myself, at least I'm a recovering engineer.

The point is that if you look at it as it's a nice toolbox that you can use whenever you like to, people choose to opt out often, and it's not a toolbox, really. It's a way of thinking and living and acting in a business. Keep reading for more details.

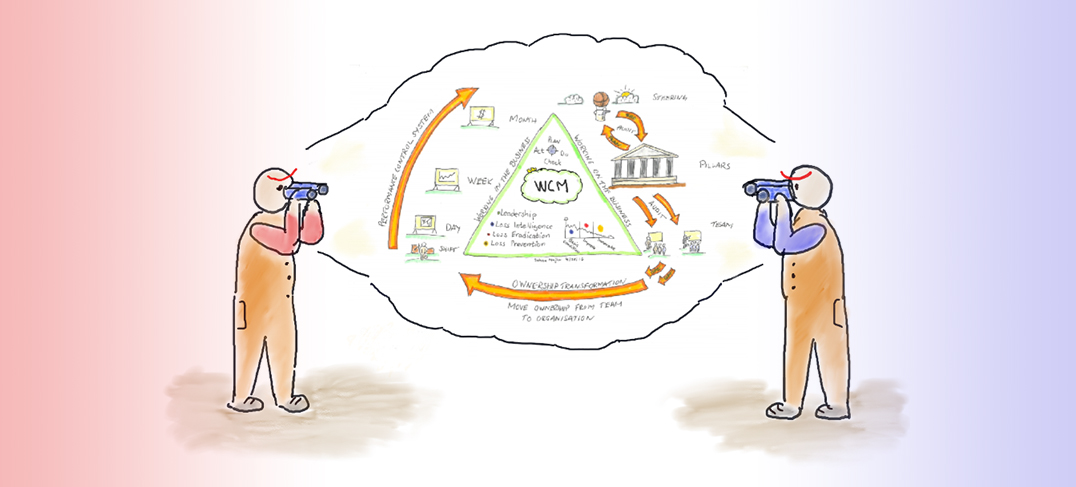

Let me take you through this model, See picture. As you know, there's no models that are perfect, but some are useful. We found this model to be quite useful in the interaction and explanation of the operational excellence system, or whatever you would call it where you work. Maybe I could say, what you want to call it, because a lot of companies have not started to build a system, they've started to train people in tools, and it doesn't hang together.

You'd be surprised how much easier it is for people when they see a picture of things that hangs together, you know what's going on. You can see that everywhere in life I guess, but especially here, when there's a lot of puzzle pieces everywhere, and you can see the total picture. It's not too bad, it helps.

As you can see, this is drawing that has three sides. One side on the right hand, is what we call working ON the business. It's about disassociating yourself from the content of the work to be able to look at the processes and see if they are meeting your requirements or not.

Think about it like this, I call it, "Watch the family, watch the movie." If you sit with your family watching a movie, you're going to see the movie. If you sit behind your family watching them when they are watching it, eating or having a drink, you will know what they do and how they act. Occasionally, you need to do that.

You need to back away and watch people working, so that you understand what is going on. That is working ON the business.

Having said that, it starts with the management team or a steering committee, whatever you want to call it, and they need to send a clear direction where they want to go. If people don't know where we are heading, they don't know what they're going to leave behind. Does that make sense? When you do any activity in Operational Excellence it most often has two results in mind. One is the deliver the business results needed and the other is to continuously build and strengthen the system. Teaching others, learning what works and what doesn't etc, is key to delivering a system. It happens in parallel to the all the activities.

You have teams of people who analyse it all, the business in different parts. It's very hard to analyse everything in one go, so you can split it up in smaller teams, in some systems like world class manufacturing, etc., it's called Pillars. You have other names and other systems, but if it as a team that takes time out, they will now back away, watch the family watch the movie, and they might concentrate on quality, or maintenance related issues, or industrial engineering issues, or production flow issues, etc. They will understand their own focus area and how they can close the gaps in your business plan.

You concentrate on different parts the business. This means that if you set up a clear direction where you want go, a vision. This team of people could say; here's why we are not there yet. They analyse that, they do something that's called loss intelligence in our lingo, they make sure they understand all the details of the losses they focus on. They will present to the Management team? Steering committee who owns the resources and after agreement launch improvement teams, they can call it Kaizen teams, improvement teams, continuous improvement teams, whatever you want call it.

It's important to be a team of people who analyzes and who improves it. We are today so disconnected from each other, from different functions in a business, and different layers in the company, with the customers, that if we never come together to learn from each other, the disconnection stays, Connections, unity that is the difference, that makes the difference. If you are connected to each other, and you're more unified, you're going to get the result. Two brains are smarter than one. More details to come on how the system is coming together, keep reading.

You put the team together, and they come up with some type of output. The problem here is that when you work on the business, it's like putting a ball up here (top of triangle in picture), and it rolls downhill, when it comes down to this point (bottom corner of triangle) it go out to outer space, never to be seen again, and that happens a lot.

People run projects, and they promote, and they show people, but struggle to sustain, and everybody knows that. I mean, seriously, we know how often that happens. Why is that? They might never have thought about holding the gains. We normally point at people and say you are supposed to do it, supervisors, first line leaders etc. Blaming them also create disconnections. How do you create a system to hold against?

The bottom of this triangle (see picture) is what we call the ownership transformation. It's about transformation in general, to transform the culture, which is important, and the knowledge and capabilities of the people to build processes, to create value, to bring results. It's also about taking the output from teams and handing it over to the line organization. This must be designed. Not to be forgotten, because then all the work you have done improving is going to be wasted soon.

On this side (right hand side of triangle in picture) is what we call working IN the business. Every day when you're working, you could potentially use the thought process of operational excellence, and what I mean with that is the only thing you can affect when you are working to change the output, there are two things. Good news, it's not 200 things, but there are still two.

You can add time. If you want to have more output, a lot of companies add time. We have overtime. In the short term, it's nice, maybe you make a little bit more money as a person and you get that task done. In the long term, you also sacrificing home life, hobbies etc., that may be bad for people, nobody wants that, plus it costs you more money as a business of course, but, you can still add time. Every person, from the CEO down to an operator, or any direction in a company, can add time normally. If you add people you by this definition add time.

The second thing you can do is you can reduce your losses. The definition of a loss is everything outside of idea. If you can do something in an ideal way, you have no losses, that's as fast as you can go. If you can get it down to zero loss, which should be your target, you have reached perfection as we know it currently. Would your target to have some losses left? It doesn't make sense. It might be hard to reach that, and sometimes impossible. I do understand that, but ... it's good to be unreasonable at times, aim for perfection.

You focus to reduce the losses and if you had zero loss with the correct amount of time added, your performance is at maximum. That's it, this means that if you work in an area and you don't know the losses you have, you cannot eradicate or minimize them. Which means that you need help from Pillars or similar to analyze it. It's good to practice to find losses, to get new eyes, to see the world with new eyes, to see where the losses are. To find opportunities.

If you don't know your losses, you don’t know your business, I would argue. Imagine if you have a 50% output of a machine. 50% of the time is losses. If you don't know them, you don’t know your area, would you agree? You need to get those eyes and learn what is going on, separate normal from abnormal etc.

Performance Control System - Working In the business

I see this as a bunch of candles on a table, they're burning, and you put your hand on top of it, you burn yourself! You burn yourself everyday on the same candle and on Friday after burning yourself every day you realize what's going to happen on Monday? I'm going to burn myself again. Really? How do you live with that? Exhausting to think about and the next week it's going to be another new candle as well that you're going burn yourself on.

In the performance control system, which is this side (right side of triangle), working in the business, it's all about understanding what losses you have, and attack them to create the output. It's not focusing on the output, because you can't focus on that. It's like focusing on the gross profit of the United States. Right? How do you do that? You focus on something you can do something about.

Operators meet starting and ending shifts, you summarize on days, you have trends, you see where you're going, so if you're getting better or worse. Do we need to do something? What is sabotaging our shifts every day. You can see trends in the week, and then attack that once a week, and every month you will add money to it.

The three sides they create Working ON the business, Transformation, Working In the business. That is Operational Excellence as a System. That is world class manufacturing, that is lean thinking, that's the system. In the core of it all is PDCA plan, do, check, act. And I know that people say, "No, no, it's DMAIC, or 8D, or A3, whatever."

Think about it like this. It doesn't have to be that complicated. If you're going to train people, and you have PDCA, if you understand that you are in good shape. You could also argue that all the other systems are linked to PDCA. Maybe you don't agree, let me know if you don't. The thing is that if there's a mind-set of following a process it's more effective.

You want to build a good leadership of managing change, create processes for loss intelligence, loss eradication, and loss prevention. Prevention means holding gains, but also making sure that the you learn from the losses you designed into your own processes, isn't repeated next time a new product is introduced or when a new machine is installed and of course when you hire new people.

This is a short simple way to explain The Operational Excellence System. We call it Operational Excellence 2.0 for the reason that we think that the heart has to be involved, it's not only the brain. A Real System considers who it supports the people to perform to their best level and to ensure they develop.

IQ*EQ=Unity and Results. One system, success. Like and share this article, please. Send an email and talk to me about that.

How and where you start to implement the System isn't easy and you can learn a great deal from somebody who has done it before.

Johan Majlov, Founder & CEO Lean Dimensions International

[email protected]