Three Phases of Change in Process Improvement

Prepare, Manage, and Sustain are not the only 3 phases of change you need to be aware of. In this article, we are describing the actual detailed...

Category: Uncategorized

Sign in

Let me talk to you about world-class manufacturing. It's a concept that's been around for many, many years. I'm also going to give you an overview about the system, because it's a very common misunderstanding, that it's a set of tools, which is kind of true, but it's not the only point. It's not a set of tools as such if you don't see it as a system.

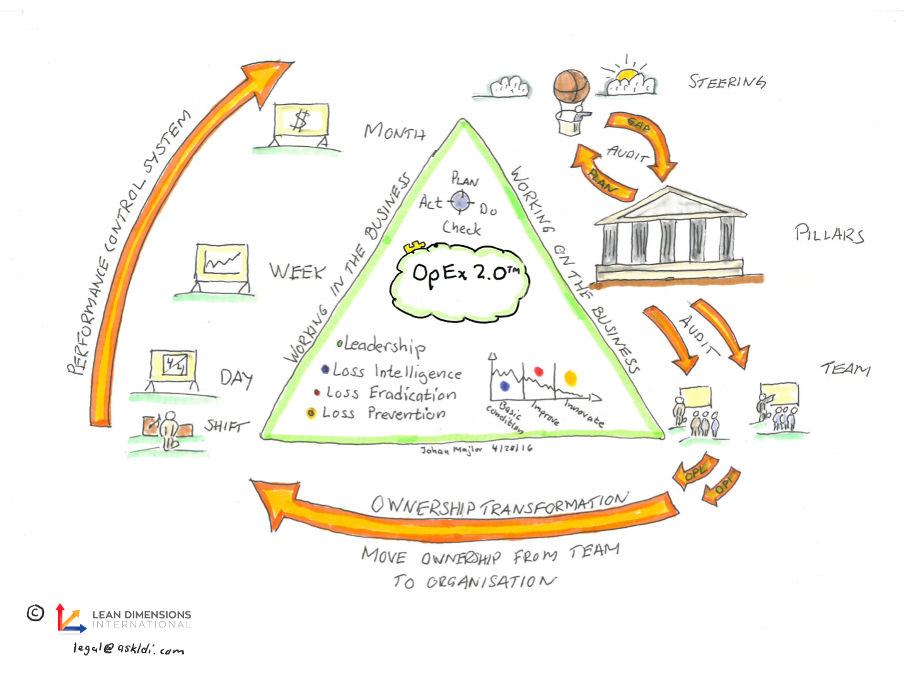

Imagine the system as a triangle. On one side of the triangle, you have all the thought processes around working on the business and what it means. Is somebody going to point out the direction? talk about what's needed for the business to be performing better in the future? Often, it is connected to a real business need, such as shorter lead times to gain more customers or lower costs, or have a better margin and maybe to compete in the market.

So, if you look at that side of the triangle, working on the business is all about understanding what's needed for the business. Understand why you are not there yet, and then start improvement activities to get to the position you want to be in the future. Working on the business is about disassociating yourself from the actual content of the work and looking at how you are working instead. We call that watch the family, watch the movie. That's what you are doing when you're analyzing what the family's doing when they're watching the movie and not worrying so much about the movie at the time if that makes sense?

At the bottom of the triangle, we have something we call transformation. One part of the transformation is to transform the output of the improvement activities, so the rest of the organization can feel that they also own the output. This is one of the most common problems that organizations are challenged with when it comes to implementing world-class manufacturing. To take the output from the projects and get everybody to feel that they have ownership of that. It's a delicate process and it's all about designing the process in the correct way and the information and communication around it.

Another part of the transformation is obviously to transform your culture that is supporting the way you want to work in world-class manufacturing. Which is often slightly different to what you have today. In short, you can say it's about supporting each other. If you're a team and you do everything you can to support the team to help them to perform. Or, if you look at your own performance and try to perform on your own, the team approach and supporting each other, that's more of the world-class manufacturing culture than it is about you as an individual. It doesn't mean that you are not important. It just means the focus is more on the team.

If you look at the left side of the triangle, that is a part where we call working in the business. When you work in the business, it's executing the normal day-to-day work that you do. In order for you to have a certain output when you work, there are only two things you can do to increase the output. One is to add time. The other one is to reduce the losses. And the definition of a loss is everything outside of the ideal. If you look at that side and you're working in the business, what if you could constantly focus on reducing the losses you have that would increase the output? Focusing on output is rarely a good idea because the output is the result of your process.

What we normally see here is that when people work, and they have a problem they start avoiding the problem because they try to get a better output. If everybody avoids the same problem in different ways, you will very soon be having a very different way of working in a team between different shifts. What we try to do is to make sure we capture all those problems in a certain way, so that we can work in the business the most effective way. World-class manufacturing is about seeing the whole picture and understanding how you work on the business, how you transform the culture and the ownership, and working in the business.

I hope this makes sense to you. I would like for you to contact me and discuss this more, to see if we can help you in any way to transform your business and get you to understand what's needed. It's a free phone call, no strings attached at all. Just contact me on the email you below and we can talk more. Please like and share this article as well, because I'm sure there are other people who like to read and understand this in a better way as well. And thank you so, so much for reading.

Johan Majlov

[email protected]