OpEx Model

About OpEx

Operational Excellence isn’t just a name, but rather, a philosophy. Used to describe how you execute your operations, to achieve your vision by making it your strategy, the term is commonly described as doing the right thing, the right way, every time, while simultaneously developing a problem-solving culture.

Operational Excellence is a term that has been developed over time. In the past, it has also been known as lean thinking, lean manufacturing, world-class manufacturing, total productive maintenance, Six Sigma, and so on. However, Operational Excellence is a common umbrella name for all the different versions of continuous improvements that exist in the world today.

Core Principles

1. Leadership

Respect, support and develop your people.

Lead and manage your change.

2. Loss Intelligence

The definition of a loss is everything outside of ideal.

Analyzing and prioritizing your losses.

3. Loss Eradication

Using the correct method to fully understand and eradicate the root of the problem.

4. Loss Prevention

Ensuring the losses do not come back again.

Ensuring the stop of the introduction of losses into processes.

5. Create value for

the Customer

Focus on what is the value the Customer really wants.

Methodologies

Definition of Operational Excellence

Operational Excellence is a system built on methodologies to enable you to execute your operations, flawlessly, using methods and tools. A method is a step-by-step approach that focuses on analyzing your losses or eradicating them. A tool is a way of organizing the work to support the method.

Examples

- 5S is a method of workplace organization

- SMED - Single Minute Exchange of Die - is a method to reduce set-up time

- VSM - Value Stream Mapping - an analysis tool to understand the flow

- Methods and tools are built around PDCA - Plan, Do, Check, Act

Challenges of OpEx model implementation

Every organization will face their own unique challenges however they can normally be grouped into two categories, technical and humanistic challenges. We can see the humanistic challenges being around 2x more than the technical. The most successful organizations have found a way to tackle the challenges together with their people and find the way together

Technical Challenges

-

Data integrity

While collecting losses, there are some common mistakes that are made. These issues can lead to the data not being trustworthy.

-

Full understanding of customer needs

The interpretation of customer needs can be wrong or misleading.

-

Prioritization

Conflicting KPIs can cloud the picture, along with a lack of correct data, causing conflict.

-

Conflicting KPI’s

If the business doesn't prioritize it's KPIs, they can appear to be conflicting.

Humanistic challenges

-

Communication

Communication is key in any organization. Without it, failure can happen.

-

Old leadership style

As times advance, old leadership styles become stale, leaving teams tired and unmotivated.

-

Ownership of problems and solutions

If there is no ownership of problems, solutions for the success of the organization can’t be proposed.

-

Not sharing the same Vision

If a team lacks the same vision, progress toward goals cannot be made, in unison.

-

Lack of training

Many teams lack proper training. Without it, work can’t be completed in the most efficient and sustainable manner.

History and Evolutions

An umbrella name for a lot of different initiatives, Operational Excellence now encompasses what has been developed in the past. These initiatives often — but not always — originate from Japan. The initiatives are typically very old — excluding Six Sigma, which is fairly new — and derived out of General Electric.

In the 1980’s we — manufacturing organizations — copied methods and tools to use for continuous improvements. However, this wasn’t very sustainable long-term.

In the 1990’s we built programs such as TQM, TPM, etc but it was viewed as something in addition to the normal workload. This also wasn’t very sustainable.

In the 2000s, we started to rebuild the whole system to ensure all pieces of the puzzle were included.

In the 2010s, Emotional Intelligence was added to the system, and more focus was placed on the people within the processes. This became extremely valuable and important, transforming sustainability within the system.

Best Practice

Organizations that implement a successful, valuable way of running their operations have a few things in common. Within these organizations, people are used to improving on a continuous basis, are well trained, and have experience in working in a highly effective way. However, one thing these organizations often don’t have to do is talk around using a particular system anymore. It’s just what they do.

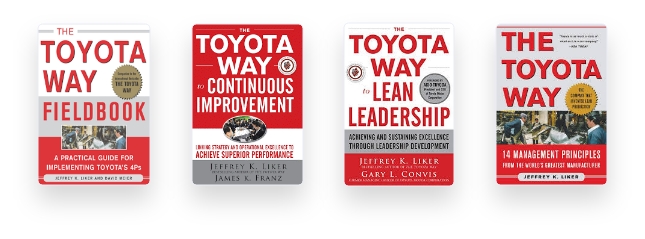

For example, if you look at Toyota — which is one of the most famous companies to show excellence in the way they work — you will see a number of positive outcomes derived from their way of working. Their efficiency has led to various achievements including increased revenue, lower overall costs, improved customer service, etc. in a very competitive business climate, the company is ranked highly, as they continuously strive for perfection in their process.

Main Contributors

Dr. Jeffrey K. Liker

He is Professor of Industrial and Operations Engineering at the University of Michigan. Dr. Liker has authored or co-authored over 75 articles and book chapters and eleven books. His articles and books have won eleven Shingo Prizes for Research Excellence and The Toyota Way also won the 2005 Institute of Industrial Engineers Book of the Year Award and 2007 Sloan Industry Studies Book of the Year. In 2012 he was inducted into the Association of Manufacturing Excellence Hall of Fame. He is a frequent keynote speaker and consultant. Recent clients include Caterpillar, Applied Materials, Siemens, Dover Industries, Kraft-Oscar Meyer, Alcatel-Lucent, Hertz, Solar Turbine, Art Van Furniture and Henry Ford Health Systems.

Hajime Yamashina

WCM is a comprehensible system to improve productivity, reduce outages and increase quality by involving all teams in lost time and resources caused by non-compliance.

Reliability of standards and performance of the production system. The power of WCM comes from improving the involvement of teams. In order to produce good products, we must have good people and involve them in continuous improvement.

Jim Collins

He is a student and teacher of what makes great companies tick, and a Socratic advisor to leaders in the business and social sectors.

Having invested more than a quarter century in rigorous research, he has authored or coauthored six books that have sold in total more than 10 million copies worldwide.

Carlo Baroncelli

He is one of the founders of EFESO Consulting and has more than 30 years experience in Operations Strategy and World Class Operation Management, leading programs for multinational companies, from Product Development to Supply Chain domain. His experience encompasses many industrial sectors, from Automotive to Pharma, Packaging, Mechanical, Paper, Steel, and Public Administration.

After Doctoring in Management Engineering, Carlo attended specialisation courses at MIT in USA and at JIPM in Japan. He holds a Degree in Industrial Engineering from Politecnico di Milano and an Operations Planning Degree at MIT. He completed the JIPM TPM course in 1984.

Sign up to learn more about the OpEx model and how it

transformed industries